What is Cost-effective Limit Sensor Mold Hydraulic Cylinder

In mold manufacturing, limit sensors (or limit switches) on hydraulic cylinders are critical for detecting position, specifically to confirm when a core or ejector pin is fully extended or retracted. This ensures the mold does not open or close prematurely, which could cause catastrophic tool damage.

Video

Parameter Table

| Model | YG140MH-1FA80BB200A-A1 |

|---|---|

| Type | Double acting |

| Bore | 80mm |

| Rod | 45mm |

| Stroke | 200mm |

| Working Pressure | 14Mpa |

| Tube | Stainless steel with magnetic sensor |

| Piston | 40Cr |

| Rod Surface | Hard Chrome Plating |

| Seal Kit | FKM, NBR |

| Operating Temperature | -40~200°C |

Details of Cost-effective Limit Sensor Mold Hydraulic Cylinder

Features of Cost-effective Limit Sensor Mold Hydraulic Cylinder

Accurate Positioning

Sensors allow for micrometer-range precision in positioning the piston, which is essential for consistent part quality in processes like injection molding.

Consistent Cycles

They ensure that movements are repeatable across millions of cycles, reducing product defects and waste.

Operational Interlocks

Limit sensors act as primary interlocks, preventing machinery from operating outside safe boundaries or overextending, which protects both operators and expensive equipment

Applications

Widely used in construction equipment, industrial machinery, agricultural vehicles, material handling, and automation systems.

FAQ

We mainly produce hydraulic cylinders, hydraulic valves, hydraulic pumps

and hydraulic system.

Yes, We offer,you need to provide the relevant authorization for the brand.

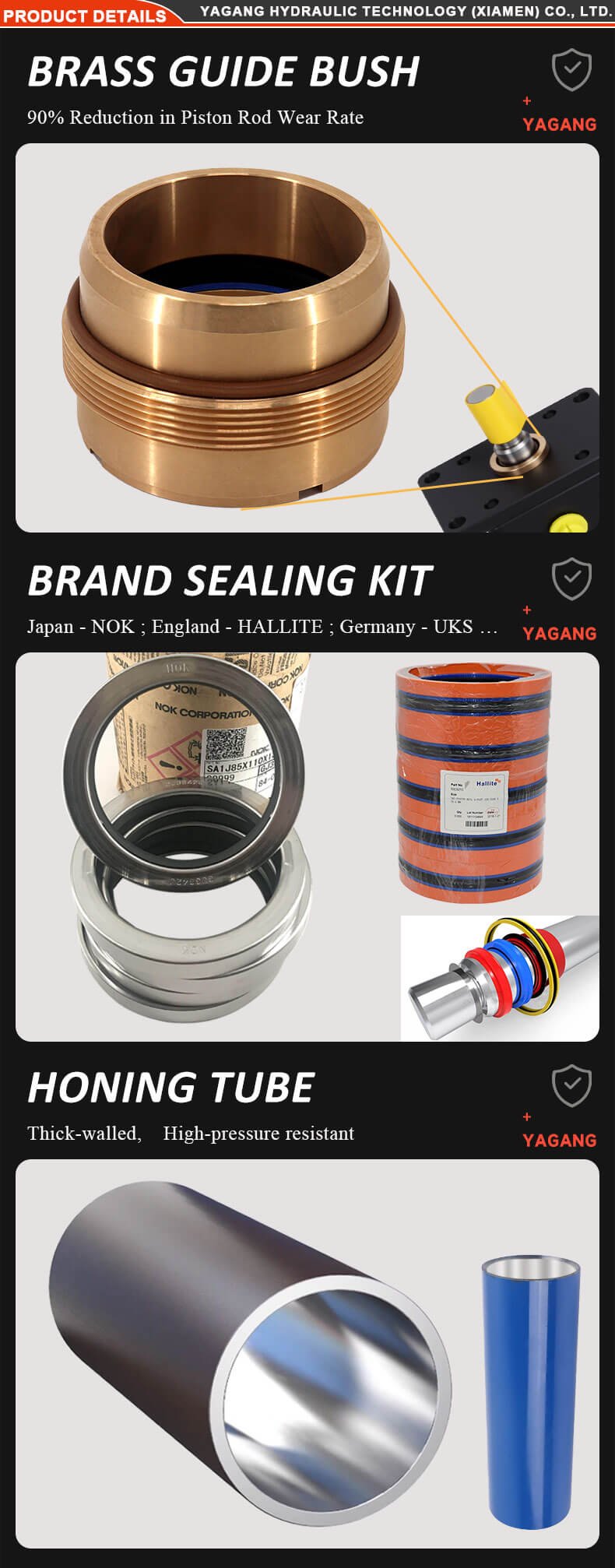

The cylinders are manufactured by advanced equipment and made under strictly quality control processing.The steel is tempered and all raw materials are good quality from world famous companies.Competitive price.

The material of the cylinder barrel commonly used by our company is 40CrMn honed tube ,while the magnetic cylinder uses 304 material for the cylinder barrel.

Our products have been exported to the United States, Germany, Japan, South Korea, Brazil and other countries and regions, helping industrial customers worldwide optimize the performance of their hydraulic systems.