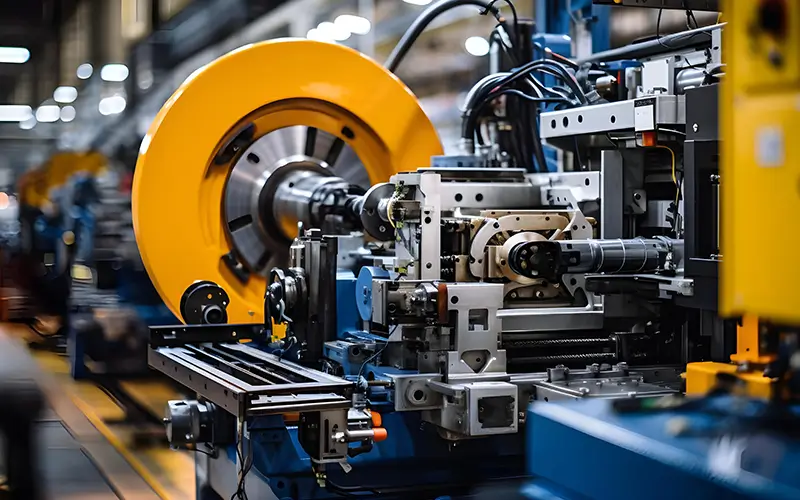

Hydraulic Cylinder Solutions for Industrial Machinery

- Home /

- Industrial Machinery

Hydraulic Cylinder Challenges

Leads to rapid seal wear, elevated oil temperature, and high leakage risk.

The repeatability and stability of cylinder movement directly impact product quality in automated lines.

Compact machine designs demand cylinders with specific dimensions and mounting styles.

- Production losses from maintenance stops are significant.

Hydraulic Cylinder Solutions For Industrial Machinery

Use high-strength, wear-resistant seal combinations (e.g., polyurethane U-cups with step seals) and wear-resistant guide bands.

Implement servo cylinders with integrated position sensors or pair with high-response proportional valves for precise closed-loop control.

Design custom compact cylinders (e.g., special flange or clevis mounts) to optimize space.

Provide condition monitoring interfaces (e.g., integrated pressure sensors) and establish predictive maintenance schedules.

Featured Hydraulic Cylinder Products

The Yagang Advantage: Engineering Excellence in Every Hydraulic Cylinder

High Reliability, Ensuring Continuous Production

Engineered for high-frequency, long-duration operation with optimized sealing and wear-resistant designs, significantly extending mean time between failures and minimizing unplanned downtime.

Precise Control, Enhancing Product Quality

Equipped with high-accuracy built-in position feedback or compatible with high-response servo controls, delivering exceptional repeatability and smooth operation to ensure process consistency.

Compact and Flexible, Adaptable to Automated Lines

Offers a wide range of custom designs and mounting configurations, enabling seamless integration into compact automated equipment spaces and supporting flexible production line layouts.

Hydraulic Cylinder Support & Engineering Q&A

We focus on maximizing reliability and service life through premium materials, precision manufacturing, and design-for-serviceability. This reduces unplanned downtime, extends maintenance intervals, and lowers long-term operating costs, offering a superior TCO compared to lower initial-price alternatives.

Standard models may ship in 2-4 weeks, whilecustom-engineered hydraulic cylinders require 3-5 weeks or more, depending on complexity.

Custom design is our strength. We will engineer hydraulic cylinders to your exact dimensional, performance, and application requirements.

Our engineers will create the drawings according to your requirements and make modifications until the drawings are approved by you.

We use high-tensile strength steels, precision-honed tubes, and hard-chromed rods. Seal selection (NBR, PU, FKM/Viton™, etc.) is critical and depends on your fluid, temperature, pressure, and speed. Our engineers will recommend the optimal combination.

Every hydraulic cylinder undergoes rigorous testing, including pressure hold, cycle, and leak tests, often exceeding standard requirements. Our ISO-based quality system controls the entire manufacturing process.

While on-site service may not be feasible, we provide unmatched remote support. You will have direct access to our technical experts via dedicated communication channels, including live video support for real-time visual troubleshooting. We supply a stocked inventory of critical spare parts for expedited shipping to keep your operations running smoothly. We are your partner, regardless of distance.