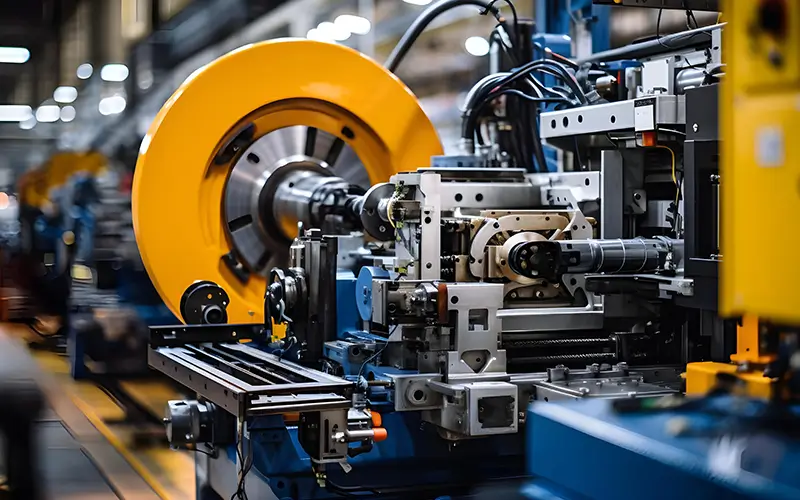

Hydraulic Cylinder Solutions for Machine Tools

- Home /

- Machine Tools

Hydraulic Cylinder Challenges

Critical during feed stages to prevent "stick-slip," which affects surface finish.

Must resist deflection under side loads to maintain machining accuracy.

Continuous operation generates heat, causing thermal expansion and potential accuracy loss.

Hydraulic Cylinder Solutions For Machine Tools

1. Employ low-friction seals and precision-honed piston rods with optimized cushioning.

2. Increase piston rod diameter, use heavy-duty guide bands and high-strength barrel materials.

3. Design forced cooling channels (inside barrel or rod) or use high-temperature stable seal materials.

Featured Hydraulic Cylinder Products

Why Choose YAGANG Hydraulic Cylinders?

Outstanding Dynamic Performance

Optimized low-friction seals and cushioning designs ensure excellent low-speed stability and micro-positioning accuracy, effectively eliminating "stick-slip" to guarantee high surface machining quality.

Exceptional Rigidity and Resistance to Eccentric Loads

Reinforced guiding and support structures, combined with high-strength materials, minimize deformation under lateral cutting forces and maintain long-term geometric accuracy of machine tools.

Performance Validated by Rigorous Testing

Each cylinder undergoes a full battery of tests—including pressure, endurance, and leak testing—exceeding industry standards. We validate performance so you can have absolute confidence in the field.

Total Cost of Ownership Advantage

Beyond the initial purchase, our cylinders deliver value through extended service life, minimal maintenance, and reduced downtime. This translates into lower operating costs and greater productivity over the long term.

Hydraulic Cylinder Support & Engineering Q&A

We focus on maximizing reliability and service life through premium materials, precision manufacturing, and design-for-serviceability. This reduces unplanned downtime, extends maintenance intervals, and lowers long-term operating costs, offering a superior TCO compared to lower initial-price alternatives.

Standard models may ship in 2-4 weeks, whilecustom-engineered hydraulic cylinders require 3-5 weeks or more, depending on complexity.

Custom design is our strength. We will engineer hydraulic cylinders to your exact dimensional, performance, and application requirements.

Our engineers will create the drawings according to your requirements and make modifications until the drawings are approved by you.

We use high-tensile strength steels, precision-honed tubes, and hard-chromed rods. Seal selection (NBR, PU, FKM/Viton™, etc.) is critical and depends on your fluid, temperature, pressure, and speed. Our engineers will recommend the optimal combination.

Every hydraulic cylinder undergoes rigorous testing, including pressure hold, cycle, and leak tests, often exceeding standard requirements. Our ISO-based quality system controls the entire manufacturing process.

While on-site service may not be feasible, we provide unmatched remote support. You will have direct access to our technical experts via dedicated communication channels, including live video support for real-time visual troubleshooting. We supply a stocked inventory of critical spare parts for expedited shipping to keep your operations running smoothly. We are your partner, regardless of distance.