Hydraulic Cylinder Solutions for Offshore & Marine

- Home /

- Offshore & Marine

Hydraulic Cylinder Challenges

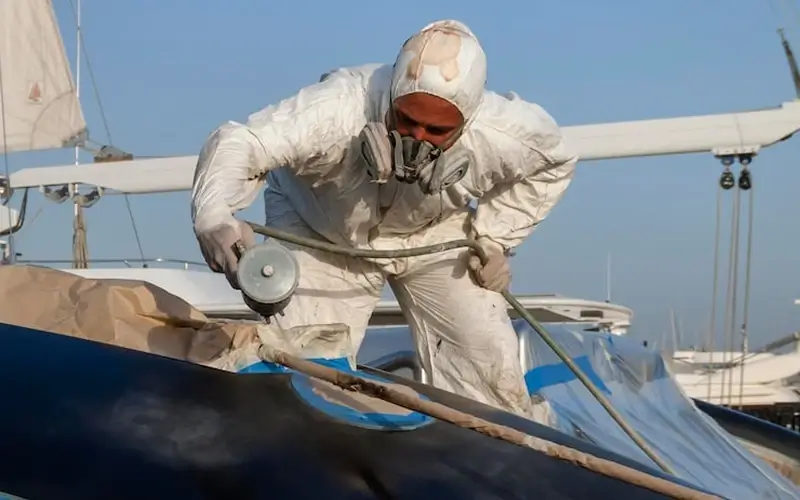

Cylinders are exposed to severe marine corrosive environments, including continuous salt spray and direct seawater immersion, which necessitate the highest levels of corrosion resistance in both materials and surface treatments.

Marine organism growth on external surfaces increases mechanical resistance, impedes heat dissipation, and can interfere with cylinder movement and operational performance.

Maintenance is prohibitively expensive and often cannot be performed in a timely manner.

Hydraulic Cylinder Solutions For Offshore & Marine

Full adoption of seawater-corrosion-resistant materials (e.g., stainless steel, copper-nickel alloys), complemented by the application of marine-grade heavy-duty anti-corrosion coatings.

Use of anti-fouling coatings on external surfaces, combined with streamlined, smooth geometries to prevent accumulation and facilitate self-cleaning.

Implementation of reliability-centered design and testing under extreme operating conditions, incorporation of redundant sealing systems, and delivery of extended service life with minimal maintenance requirements.

Featured Hydraulic Cylinder Products

Why Choose YAGANG Hydraulic Cylinders?

Premium Marine Corrosion Protection

Utilizes full-range seawater-resistant materials (e.g., stainless steel, copper-nickel alloys) with heavy-duty anti-corrosion coatings to withstand the harshest salt spray and immersion environments.

Anti-Fouling and Long-Term Reliability

Surface treatments prevent marine organism adhesion, offering extended design life and maintenance cycles far exceeding land-based equipment, suitable for challenging and costly offshore maintenance conditions.

Compliance with Marine Engineering Standards

Design and manufacturing adhere to relevant classification society and marine engineering standards, with optional redundant sealing and safety systems to ensure guaranteed reliability.

Hydraulic Cylinder Support & Engineering Q&A

We focus on maximizing reliability and service life through premium materials, precision manufacturing, and design-for-serviceability. This reduces unplanned downtime, extends maintenance intervals, and lowers long-term operating costs, offering a superior TCO compared to lower initial-price alternatives.

Standard models may ship in 2-4 weeks, whilecustom-engineered hydraulic cylinders require 3-5 weeks or more, depending on complexity.

Custom design is our strength. We will engineer hydraulic cylinders to your exact dimensional, performance, and application requirements.

Our engineers will create the drawings according to your requirements and make modifications until the drawings are approved by you.

We use high-tensile strength steels, precision-honed tubes, and hard-chromed rods. Seal selection (NBR, PU, FKM/Viton™, etc.) is critical and depends on your fluid, temperature, pressure, and speed. Our engineers will recommend the optimal combination.

Every hydraulic cylinder undergoes rigorous testing, including pressure hold, cycle, and leak tests, often exceeding standard requirements. Our ISO-based quality system controls the entire manufacturing process.

While on-site service may not be feasible, we provide unmatched remote support. You will have direct access to our technical experts via dedicated communication channels, including live video support for real-time visual troubleshooting. We supply a stocked inventory of critical spare parts for expedited shipping to keep your operations running smoothly. We are your partner, regardless of distance.