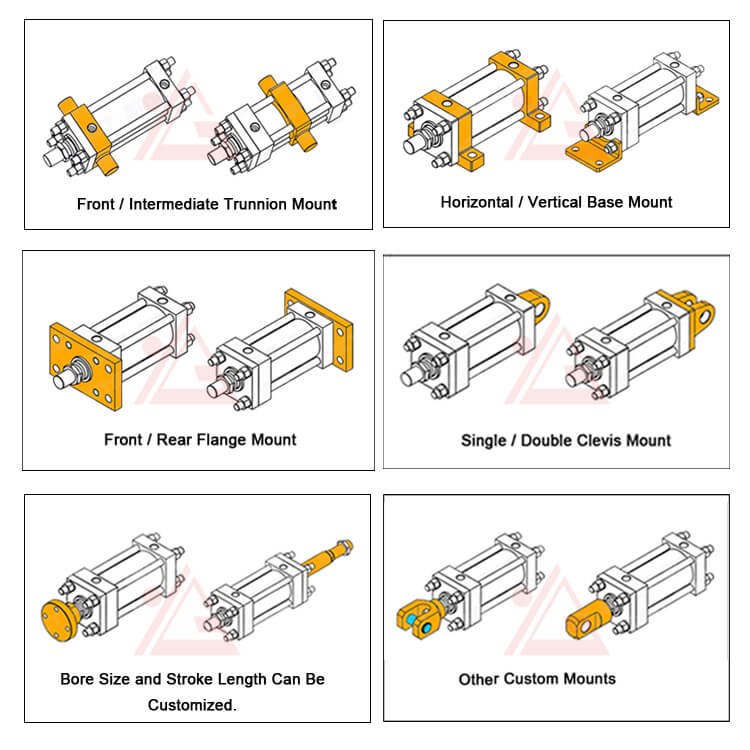

What is Cost-effective Adjustable Stroke Compact Hydraulic Cylinder for Automation

Users can limit the stroke length through mechanical stops, external adjusters, or integrated sensors (like magnetic switches) that define the “home” and “end” positions.Despite their small footprint, they can operate at high pressures (often up to 16–21 MPa or 160–210 bar) to provide significant clamping or lifting power.

Video

Parameter Table

| Model | YG160SD-1LA40-50T-20 |

|---|---|

| Type | Double acting |

| Bore | 40mm |

| Rod | 22mm |

| Stroke | 5-100mm |

| Working Pressure | 16Mpa |

| Tube | 45# Steel |

| Piston | 40Cr |

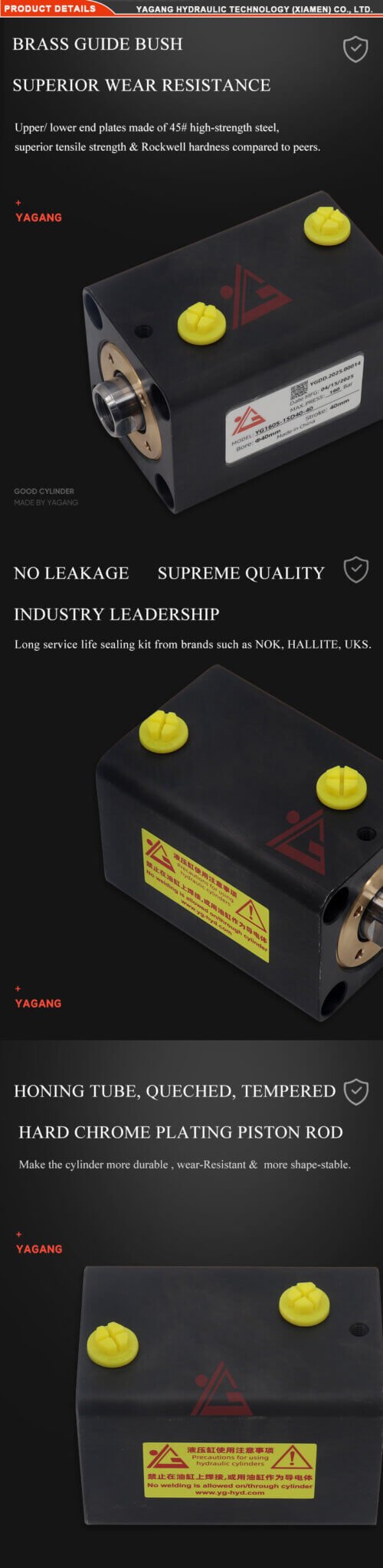

| Rod Surface | Hard Chrome Plating |

| Seal Kit | FKM, NBR |

| Operating Temperature | -40~200°C |

Details of Cost-effective Adjustable Stroke Compact Hydraulic Cylinder for Automation

Features of Cost-effective Adjustable Stroke Compact Hydraulic Cylinder for Automation

Cost-Effectiveness

A single adjustable cylinder can replace multiple fixed-stroke cylinders, reducing overall equipment costs and simplifying inventory management.

Precision & Control

These cylinders are designed for high-density layouts requiring accurate, repeatable movements. Some models include adjustable cushioning at the end-stroke to decelerate the piston and prevent "metal-to-metal" impact.

High Power-to-Size Ratio

Despite their small footprint, they can generate significant force, often operating at high pressures (e.g., 3.5 MPa to 500 bar depending on the model).

Applications

Widely used in construction equipment, industrial machinery, agricultural vehicles, material handling, and automation systems.

FAQ

Our products feature high performance, higher cost performance and durability.

hydraulic cylinder, hydraulic valve, hydraulic pumps.

We have 3 production lines and can produce more than 4,00 hydraulic products every day.

Of course, We will keep track of the order throughout the process and promptly inform you of the production progress.

We will use plywood carton for packing.