What is Engineering Standard Magnetic Double Acting Tie-Rod Stainless Steel Hydraulic Cylinder

Magnetic tie-rod hydraulic cylinders are a versatile and reliable solution for industrial automation where piston position monitoring is crucial. Key manufacturers offer a variety of options designed to industry standards, providing precise control and durable performance in medium-pressure applications.

Video

Parameter Table

| Model | YG70HR-1FA50BBB200AB-EKM |

|---|---|

| Type | Double acting |

| Bore | 50mm |

| Rod | 28mm |

| Stroke | 200mm |

| Working Pressure | 7Mpa |

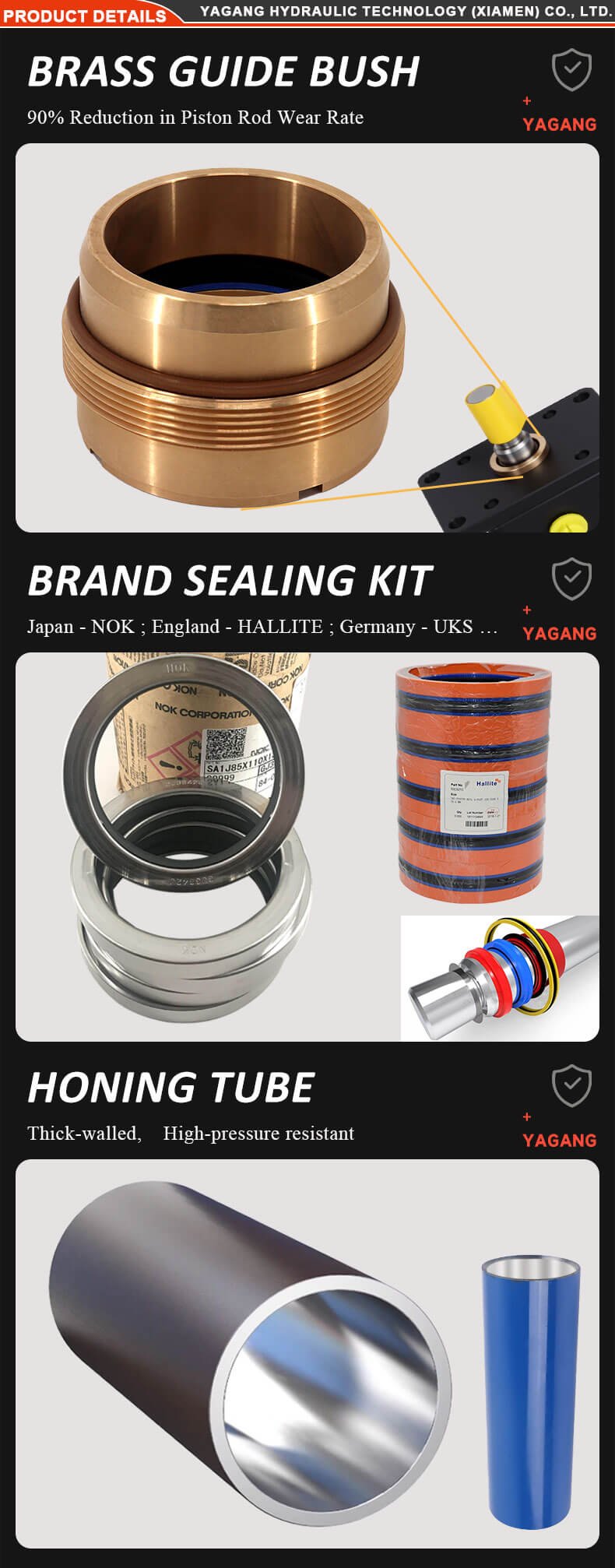

| Tube | Stainless steel with magnet |

| Piston | 40Cr |

| Rod Surface | Hard Chrome Plating |

| Seal Kit | FKM, NBR |

| Operating Temperature | -40~200°C |

Details of Engineering Standard Magnetic Double Acting Tie-Rod Stainless Steel Hydraulic Cylinder

Features of Engineering Standard Magnetic Double Acting Tie-Rod Stainless Steel Hydraulic Cylinder

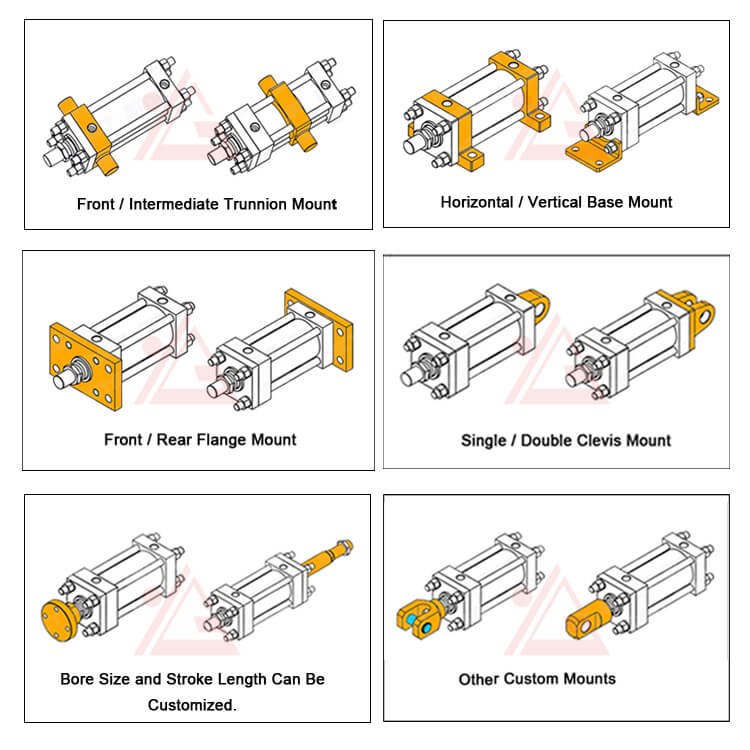

Installation/Retrofitting

Depending on the sensor type, the non-intrusive design can eliminate the need for complex external brackets or machining costs during installation. External-mount options also allow for easy retrofitting of older cylinders.

Simplified Maintenance

The tie-rod design inherently allows for easy disassembly with standard tools, which simplifies routine maintenance and repair tasks, minimizing downtime.

Predictive Maintenance

: Monitoring motion patterns and delays via sensor data can help identify potential issues like seal wear or fluid leaks before a major breakdown occurs, enabling proactive maintenance

Applications

Widely used in construction equipment, industrial machinery, agricultural vehicles, material handling, and automation systems.

FAQ

Monthly output 400PCS, our products & service cover 20+ countries and regions.

Of course, every one of our orders can be delivered to the customers on time.

Usually 15-25 days, depending on product complexity.

Hard chrome plating (30-50μm, HV≥800), with optional laser cladding for extreme wear resistance.

hydraulic cylinder, hydraulic valve, hydraulic pumps.