What is High Precision Manufacturing Magnetic Dual-axis Stainless Steel Hydraulic Cylinders

A “magnetic dual-axis tie rod hydraulic cylinder” is a specialized double-acting, double-rod hydraulic cylinder with an integrated magnet in the piston for position sensing, typically used in automation for stable and precise linear motion. The “dual-axis” likely refers to the “double rod” configuration, which provides balanced force and stability.

Video

Parameter Table

| Model | YG70HRD-1FA80BB150AB-K-T2-50 |

|---|---|

| Type | Double acting |

| Bore | 80mm |

| Rod | 45mm |

| Stroke | 150mm |

| Working Pressure | 7Mpa |

| Tube | Stainless steel with magnet |

| Piston | 40Cr |

| Rod Surface | Hard Chrome Plating |

| Seal Kit | FKM, NBR |

| Operating Temperature | -40~200°C |

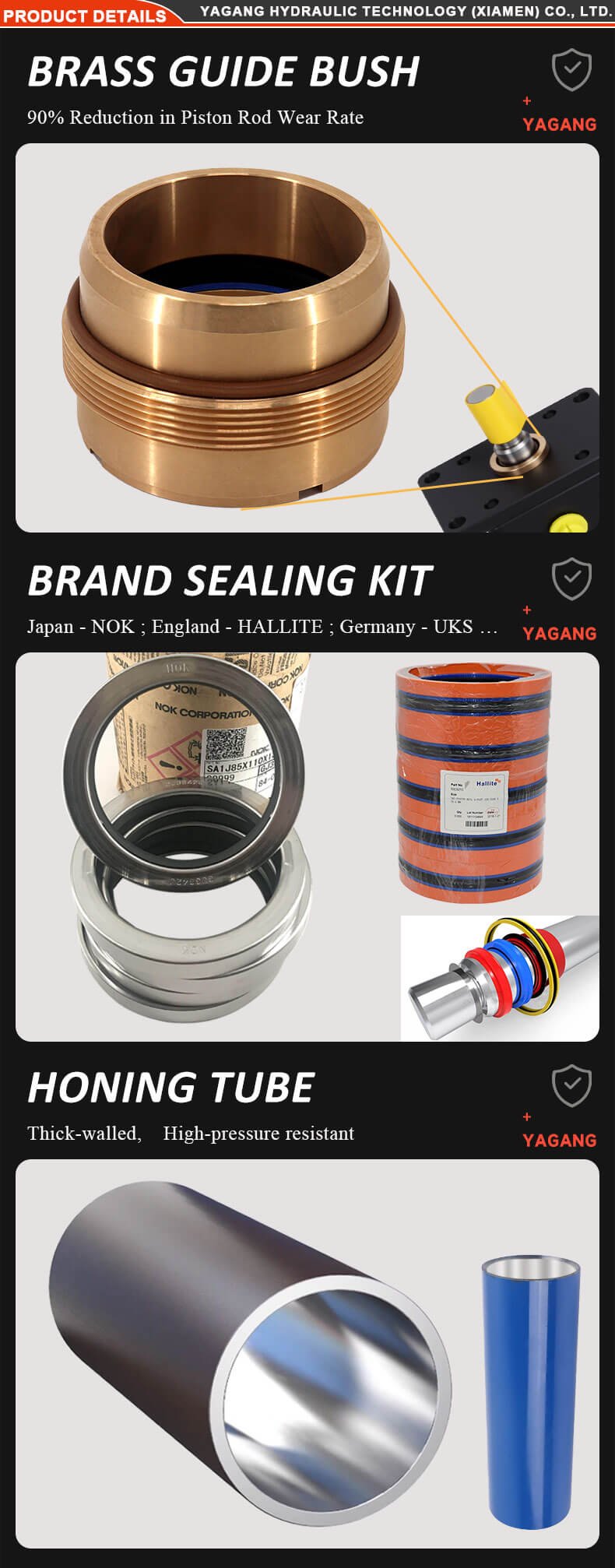

Details of High Precision Manufacturing Magnetic Dual-axis Stainless Steel Hydraulic Cylinders

Features of High Precision Manufacturing Magnetic Dual-axis Stainless Steel Hydraulic Cylinders

Exact Positional Control

The magnetic sensors provide continuous, real-time feedback on the piston's exact location, allowing for precise control and stopping at any point along the stroke. This is crucial for applications like robotics, CNC machines, and assembly lines.

Repeatable Motion

This setup ensures consistent and accurate movement for repetitive tasks, which is essential for uniform product quality in automated manufacturing processes

Seamless Integration

The sensors facilitate seamless integration with Programmable Logic Controllers (PLCs) and control systems, enabling sophisticated automation and dynamic adjustments based on real-time data.

Applications

Widely used in construction equipment, industrial machinery, agricultural vehicles, material handling, and automation systems.

FAQ

Monthly output 400PCS, our products & service cover 20+ countries and regions.

Give us the correct nameplate photo with model number or drawing,We will provide you with the drawings based on the information you have provided for your confirmation.

Yes. We offer: Factory photos/videos (production lines, facilities, etc.).Business licenses and certifications (e.g., ISO, CE,Yagang brand registration). Audit reports (third-party or client-conducted).

Absolutely! We welcome client visits and audits. Contact us to arrange a tour.

You can first contact us and inform us of the product specifications, model or drawings you desire. We will provide you with a quote and confirm the transportation method as soon as possible. Subsequently, we will draft the order for you. Please confirm the order amount and make the payment.