What is ISO High Precision Thin-type Double Acting Cylinder

The primary advantage of magnetic compact hydraulic cylinders is their ability to provide precise control and feedback within minimal space

They are optimized for installations with limited space, offering high force output relative to their size

Constructed from high-quality materials like anodized aluminum or steel, they are designed to withstand demanding industrial environments.

Video

Parameter Table

| Model | YG160SR-1SD32-80 |

|---|---|

| Type | Double acting |

| Bore | 32mm |

| Rod | 18mm |

| Stroke | 80mm |

| Working Pressure | 16Mpa |

| Tube | 45# Steel |

| Piston | 40Cr |

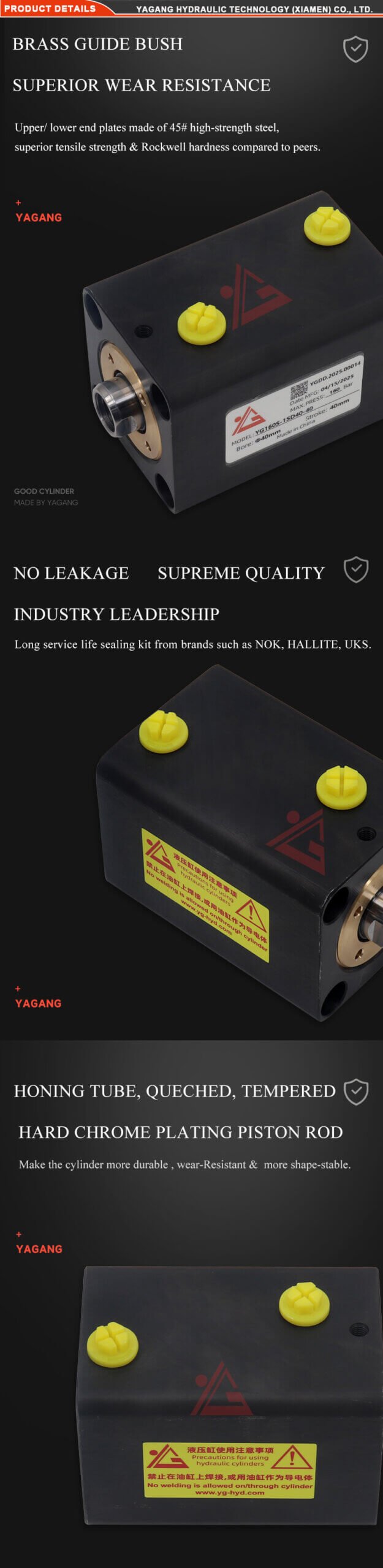

| Rod Surface | Hard Chrome Plating |

| Seal Kit | FKM, NBR |

| Operating Temperature | -40~200°C |

Details of ISO High Precision Thin-type Double Acting Cylinder

Features of ISO High Precision Thin-type Double Acting Cylinder

Extreme Space Efficiency

Their "compact" design features a reduced overall body length compared to standard cylinders, allowing them to fit into tight machinery layouts like injection molds or robotic tooling.

Reduced Maintenance

The non-contact nature of magnetic sensing eliminates the need for mechanical switches or internal rods that are prone to wear or failure, while robust materials like chrome-plated steel or aluminum alloy resist corrosion.

Precision & Non-Contact Sensing

Integrated magnets allow for real-time piston position detection via external sensors without physical wear, resulting in high repeatability (often down to 0.1 mm) and a longer operational lifespan.

Applications

Widely used in construction equipment, industrial machinery, agricultural vehicles, material handling, and automation systems.

FAQ

Give us the correct nameplate photo with model number or drawing,We will provide you with the drawings based on the information you have provided for your confirmation.

Of course, We will keep track of the order throughout the process and promptly inform you of the production progress.

We are a direct manufacturer with our own factory located in Xiamen,China. We oversee the entire production process to ensure quality control and competitive pricing.

In-house QC team: Strict inspections at each production stage.

Of course you can,You need to provide the relevant authorization for the brand.