What is Long-life Double Acting Tie-Rod Stainless Steel Hydraulic Piston Cylinder

Magnetic tie-rod hydraulic cylinders are a versatile and reliable solution for industrial automation where piston position monitoring is crucial. Key manufacturers like Parker offer a variety of options designed to industry standards, providing precise control and durable performance in medium-pressure applications.

Video

Parameter Table

| Model | YG35H-1FA63SB200AB-K |

|---|---|

| Bore | 65mm |

| Rod | 22mm |

| Stroke | 200mm |

| Working Pressure | 3.5Mpa |

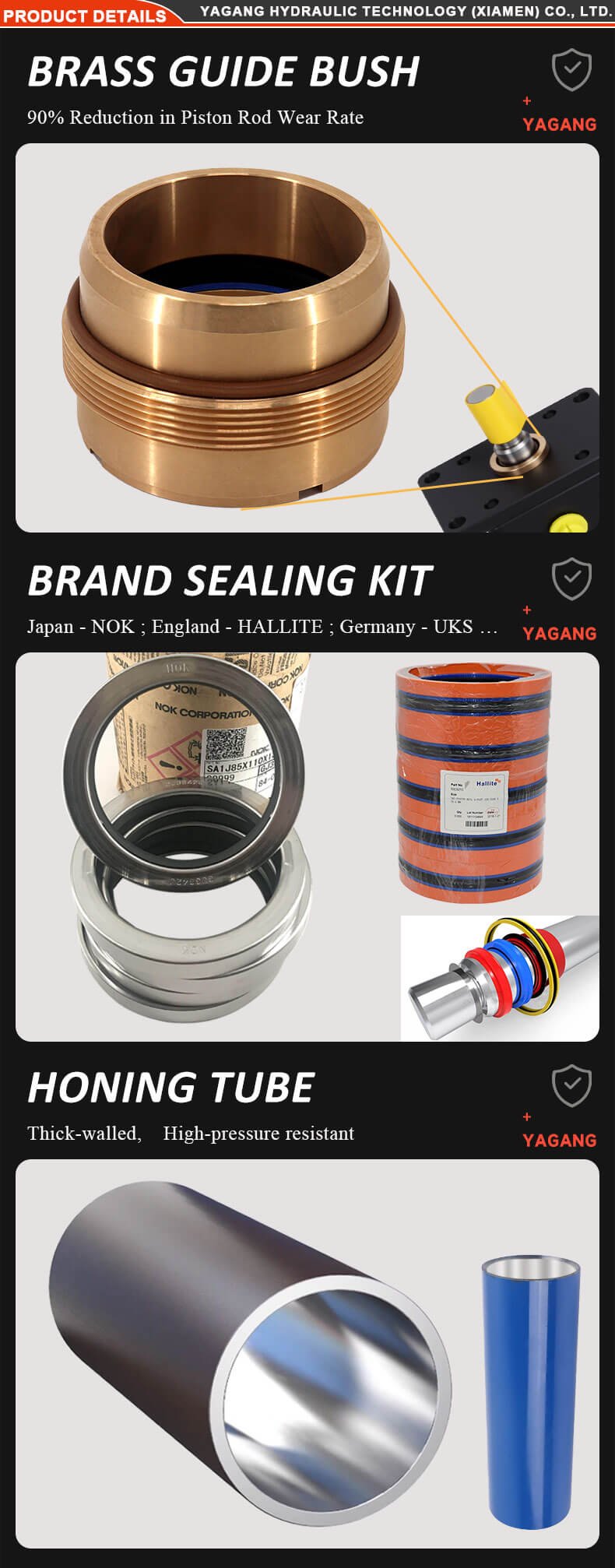

| Tube | 40CrMn |

| Piston | 40Cr |

| Rod Surface | Hard Chrome Plating |

| Seal Kit | FKM, NBR |

| Operating Temperature | -40~200°C |

Details of Long-life Double Acting Tie-Rod Stainless Steel Hydraulic Piston Cylinder

Features of Long-life Double Acting Tie-Rod Stainless Steel Hydraulic Piston Cylinder

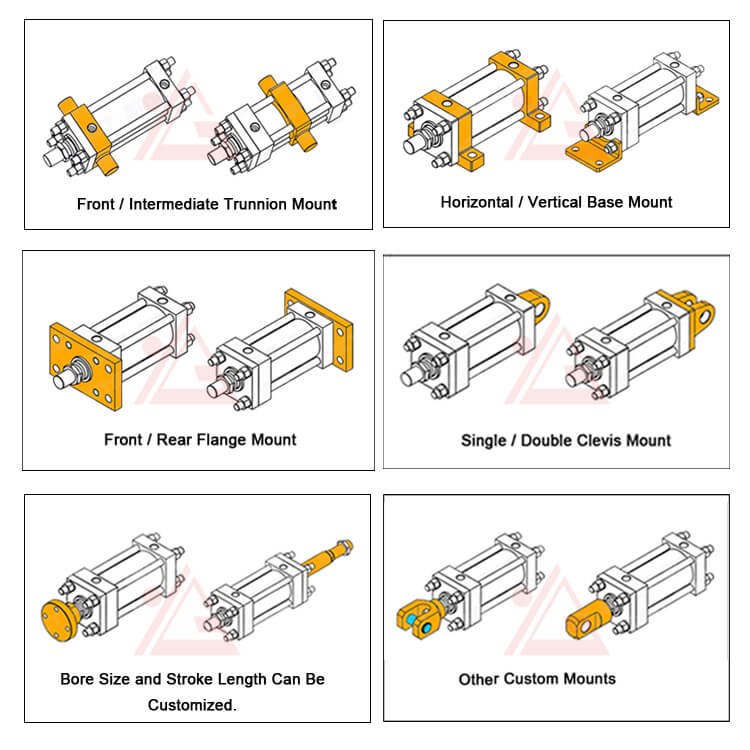

Installation/Retrofitting

Depending on the sensor type, the non-intrusive design can eliminate the need for complex external brackets or machining costs during installation. External-mount options also allow for easy retrofitting of older cylinders.

Simplified Maintenance

The tie-rod design inherently allows for easy disassembly with standard tools, which simplifies routine maintenance and repair tasks, minimizing downtime.

Predictive Maintenance

Monitoring motion patterns and delays via sensor data can help identify potential issues like seal wear or fluid leaks before a major breakdown occurs, enabling proactive maintenance

Applications

Widely used in construction equipment, industrial machinery, agricultural vehicles, material handling, and automation systems.

FAQ

Email us. We'll provide pricing, and lead time based on your quantity and customization level.

No MOQ, 1 pc can be customized.

Our products have been exported to the United States, Germany, Japan, South Korea, Brazil and other countries and regions, helping industrial customers worldwide optimize the performance of their hydraulic systems.

Of course, We will keep track of the order throughout the process and promptly inform you of the production progress.

We have 3 production lines and can produce more than 4,00 hydraulic products every day.